The chemical composition of this alloy in T7451 as received condition is described in Table 1. Samples were prepared from a plate of aluminium AA7050-T7451 supplied by Embraer S.A. T6I4-65 (underaged condition with interrupted ageing). T6 (underaged condition with simple ageing) and The condition as received T7451 (overageing with double ageing) Three different conditions of ageing heat treatment were chosen to produce different densities of the precipitated phase in an aluminium alloy matrix: one was overageing and two, underageing: Therefore, with the objective to explore the AFM technique, the present work made a correlation between results of surface roughness in AFM with the density of a precipitated phase in matrix on an AA7050 aluminium alloy obtained by TEM. AFM is little explored regarding the characterization of the microstructure of metallic alloys. 87 p.116 -128, 2014., the use of atomic force microscopy (AFM) shows evidences of the quantification of the η' and η precipitates with the collaboration of microscopy techniques (TEM and SEM). Comparative quantification and statistical analysis of η' and η precipitates in aluminum alloy AA7075-T651 by TEM and AFM. Study of precipitates formed in a wrought aluminum alloy by means of atomic force microscopy. Unfortunately, this technique requires a careful sample preparation to obtain a very thin substrate, smaller than 100 nm. The technique that is most utilized to characterize nanometrics precipitates is the TEM.

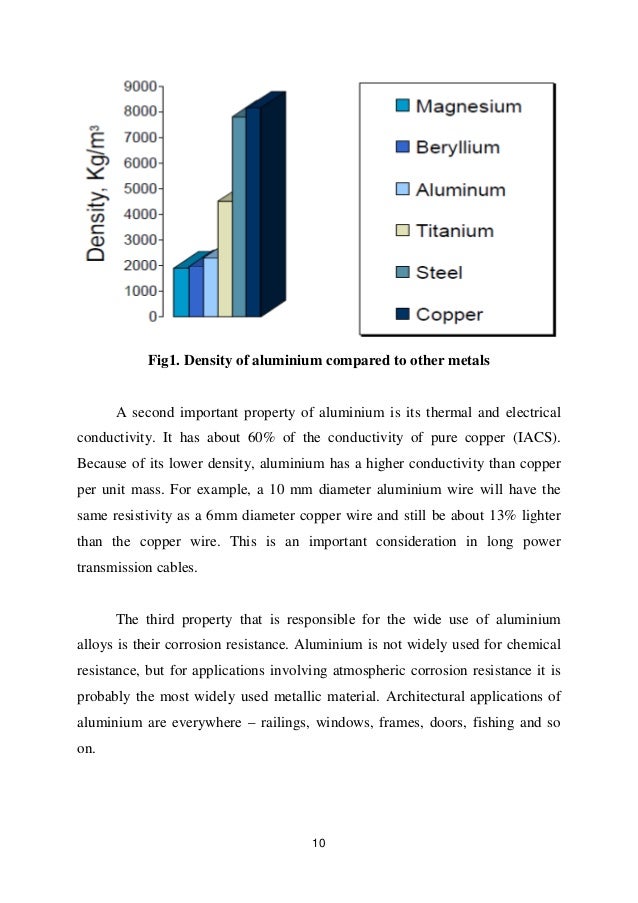

#Density of aluminum series

The quantification of these precipitated particles in metallic alloys has been made by a series of characterization techniques, especially by transmission electronic microscopy and scanning electronic microscopy (TEM and SEM). This precipitation can be carried out only in a simple ageing stage (condition T6), in multiple steps at different times and temperatures, called double ageing (T7451 condition), or by secondary precipitation ageing known in the T6 condition as interrupted followed by ageing for long periods at temperatures around 65 ✬, as well as the so-called reversal treatment and re-ageing. Temperature and ageing time are the main parameters for the variation in the final formation of precipitates. Physical metallurgy and advanced materials. Smallman and Ngan, 2007 SMALLMAN, R.E., NGAN, A.W.

(DPhil Thesis) Brent et al., 2004 BRENT L. Netherlands: Netherlands Institute for Metals Research, 2004. Local Electrochemical Behavior of 7XXX Aluminum Alloys. Handbook of aluminum: physical metallurgy and process.

The size, morphology and distribution of precipitates can result in improvements in the mechanical properties ( Katgerman and Eskin, 2003 KATGERMAN, L., ESKIN, D. The nucleation of these precipitates can occur homogeneously (uniform and non-preferential) and heterogeneously (preferential) in specific places such as grain boundaries, dislocations and vacancies. Katgerman and Eskin, 2003 KATGERMAN, L., ESKIN, D.

GP - zones in Al-Zn-Mg Alloys and their Role in Artificial Aging. The sequence of precipitation for alloys of Al-Zn-Mg-Cu is generally summarized as: supersaturated solid solution (SSSS) → GP zones → intermediate precipitates η' → equilibrium precipitates η ( Berg et al., 2001 BERG, L. Consequently, Guinier-Preston (GP) zones and the η' (MgZn 2) and η (MgZn 2) precipitates are the main phases present in alloys of the 7XXX series, and the η' phase is primarily responsible for the increased resistance. The mechanical strength of these alloys is increased through precipitation of a fine dispersed phase through a heat treatment process called precipitation ageing. In the 7XXX series alloy, the base Al-Zn-Mg-Cu, is widely used in the aircraft industry. The experimental results showed that the AFM technique proved to be a valid qualitative tool and may complement the results obtained by TEM an exploratory analysis for the microstructures.Īluminium alloy AA7050 interrupted ageing secondary precipitation TEM and AFM For this, three conditions for heat treatment of an aged aluminium alloy AA7050 were therefore chosen to produce different density and sizes of precipitates. This study investigated a possible alternative quantification of the precipitates by atomic force microscopy (AFM) to complement the technique by TEM. Typically, these precipitates of nanometric sizes are mainly characterized by transmission electron microscopy (TEM), which in this particular case, requires a very meticulous preparation. Especially in the AA7050 alloy, after ageing heat treatment, the particles responsible for the hardening become very thin. The quantification of nanometric precipitates in Al-Zn-Mg-Cu alloys has been performed by a series of experimental techniques.

0 kommentar(er)

0 kommentar(er)